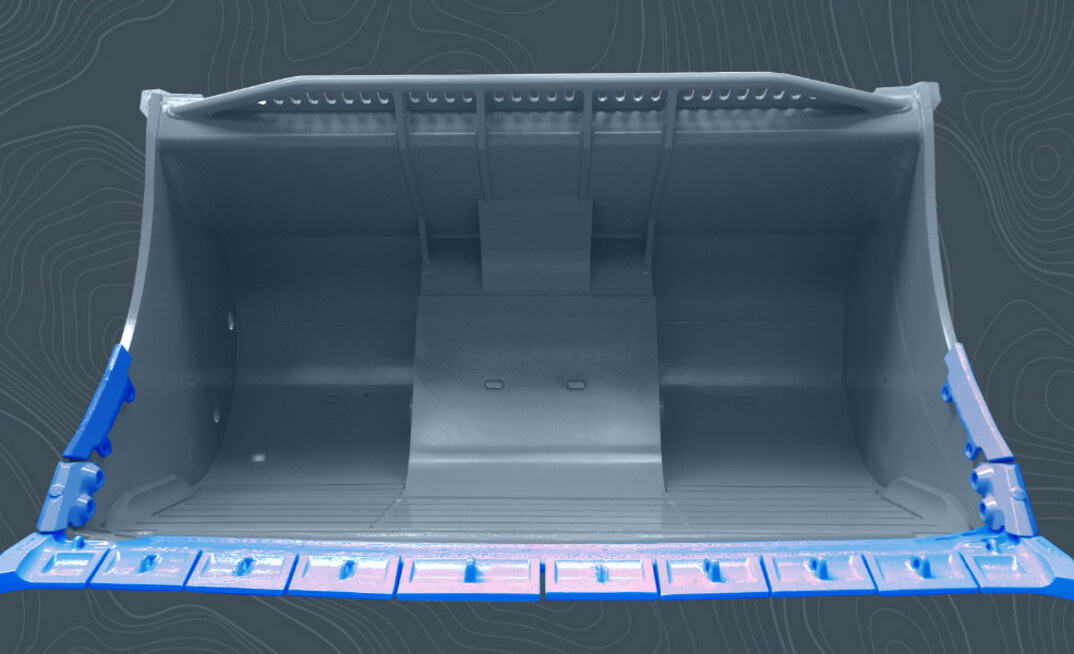

CR Mining will partner with global bucket manufacturers to introduce a best-in-class bucket for LHD loaders. This new bucket has been designed and engineered to reduce cost of maintenance and maintenance-related downtime.

Regardless of commodity, all miners share a single goal: to move the most dirt in the least amount of time.

Achieving this goal requires machines with high availability to be constantly digging. When machines are subject to high maintenance requirements, impacting availability, the result is reduced productivity.

A Low-Maintenance LHD Bucket?

Over the past three years, we've spent hundreds of hours underground across continents, talking to customers and learning about their requirements.

Regardless of the application, we heard the same concerns repeatedly. Existing LHD bucket designs caused too much maintenance downtime and were not meeting miners' operational needs.

Our customers needed LHD buckets that were lower maintenance. The current maintenance costs are too high, from related machine downtime to ongoing labor shortages.

Two significant problems stood out:

- The need to frequently change out multiple worn heel blocks on buckets was both costly and time-consuming.

- Bulkheads were causing damage to mine support structures and utilities, as well as increasing maintenance requirements.

The Pursuit of Bucket Perfection

We're driven by innovation, so we got to work using our experience as the GET experts to find a solution.

The collaboration with CEB was a natural fit as one of the world's leading LHD bucket innovators.

Combining our expertise in castings with theirs in buckets, the outcome was a bucket built to push the limits of productivity.

Stronger, More Productive Buckets

The next-generation LHD bucket tackles the problem of high maintenance requirements from multiple angles.

The bucket design simplifies maintenance by removing bucket features that create additional costs and optimizing material selection and placement.

High-quality alloy castings in corners mean no mechanic or weld-on heel blocks. These castings have recently lasted for two years (approximately 11,000 hours) before changeout on a LHD bucket digging in New South Wales.

Tapered top corners reduce the risk of damage to underground utilities and support, with the added benefit of increasing the bulkhead strength of the bucket.

"We took customer feedback and applied it to create this new bucket, which is well suited to every possible application. Most of our customers are actually contract miners, so it's especially important that they are able to maximize machine uptime and availability," says Quintin Nienaber, General Manager - Underground.

The result is a bucket that provides the highest possible machine uptime for LHDs.

Looking Forward

Internationally, buckets will be built by our in-country partners.

Each bucket is made to order, available for any LHD model, and customized to solve specific concerns.

"Our team thrives on customer collaboration and deeply understanding each sites' operations, so we've extended this approach to the buckets," says Nienaber.

Buckets will come with CR's Wearpact GET. Wearpact, our flagship continuous edge lip for LHDs, is also designed to improve productivity through higher machine availability, making for a super duo.

For more information on the benefits of CR's Low Maintenance Bucket, contact us at globalsales@crmining.com

ABOUT THIS COMPANY

CR Powered by Epiroc

CR Powered by Epiroc engineers advanced mining products and digital solutions for surface and underground mining equipment, fixed plant, and wear parts. Its advanced physical and digital solutions help the world’s best miners unlock productivity, enhance safety, and reduce emissions.

HEAD OFFICE:

- Building 5, Level 3, 747 Lytton Rd Murarrie QLD 4172, Australia

- Phone: +61 7 3902 3800

- Email : marketing@crmining.com

- Web: crmining.com